PSA technology is popular for its high energy efficiency and simple operation. It is based on the difference in the adsorption capacity of specific adsorbents (such as activated carbon or molecular sieves) for different gases. Under high pressure, specific gases (such as oxygen or nitrogen) are adsorbed by the adsorbent. Subsequently, by reducing the system pressure, the adsorbed gas is released, thus achieving separation. PSA systems usually include multiple adsorption towers, and while one tower is adsorbing, another is regenerating (releasing gas) to achieve continuous operation. PSA is suitable for small to medium-sized gas production, such as hospital oxygen supply or industrial site nitrogen supply.

PSA is a technology for separating gas mixtures and is widely used in fields such as oxygen and nitrogen production.

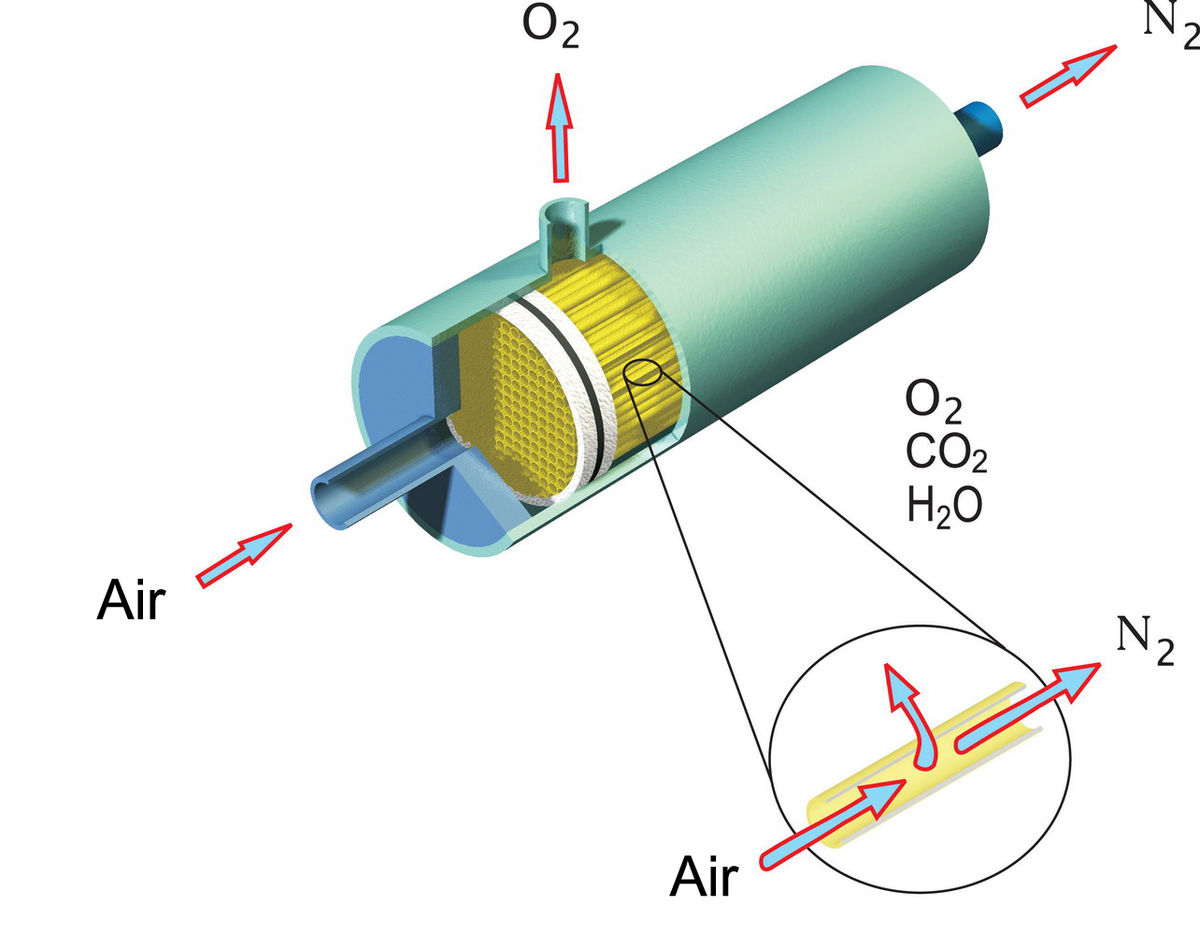

Membrane separation uses specially made semipermeable membranes to separate gas molecules based on their size and diffusion rate. These membranes are usually made of special polymers or ceramic materials that selectively allow certain gas molecules to pass through while blocking other molecules. For example, some membranes allow smaller oxygen molecules to pass through while blocking larger nitrogen molecules. Membrane separation equipment is compact, easy to operate, and has low maintenance costs. It is very suitable for occasions where medium-purity gas is required, such as nitrogen in food packaging or gas purification in certain chemical processes.

Air separation system uses air as raw material, converts air into liquid through compression cycle deep freezing, and then gradually separates and produces inert gases such as oxygen, nitrogen and argon from the liquid air through distillation. It is widely used in traditional metallurgy, new coal chemical industry, large-scale nitrogen fertilizer, professional gas supply and other fields.

The compressed air from the air compressor is precooled and purified by the air precooling system, and the molecular sieve removes impurities such as moisture, carbon dioxide, and hydrocarbons. Part of the air is directly sent to the upper tower of the distillation tower, and the other part enters the expander for expansion and refrigeration, and is sent to the lower tower. In the distillation tower, after the rising steam and the falling liquid exchange heat, high-purity nitrogen can be obtained at the top of the upper tower, and high-purity oxygen can be obtained at the bottom of the upper tower.